HullWiper collects marine fouling removed from hulls, rather than polluting local port water and risking the spread of harmful invasive species. Captured residues are pumped into a filter unit and then deposited into dedicated drums onshore, which are collected by a locally-approved environmental waste disposal company. The effectiveness of HullWiper's filter system in cleaning the waste water has been verified by AMT Environmental, an environmental analysis and consulting professional. A clean hull also improves a vessel's speed and reduces carbon emissions.

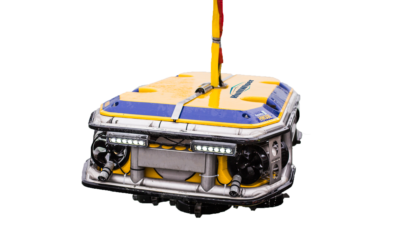

HullWiper sprays adjustable high-pressure seawater jets directly onto a ship's hull at a very high velocity to dislodge waste materials, without using scrubbing, harsh chemicals or abrasive materials required for traditional methods. Unlike traditional brush cleaning, HullWiper uses high-pressure jets for cleaning, thus leaving expensive antifouling surfaces smooth, intact and undamaged. The use of high-pressure jets for cleaning ensures that HullWiper does not damage the ship's expensive antifouling coatings.

Variable and increased speed dependent on biofouling and coating condition

Does not damage hull antifouling coating

Uses seawater as a medium for hull cleaning

Extremely good power and stability

Fast mobilisation / demobilisation

Operational 24/7

Kevlar armoured cable length 350m, outer diameter 24mm

CD100 135 l/min

Diesel driven 60Hz/400V super silence

DCN Australian Shipping Maritime Industry Awards

Seatrade Cruise Awards 2019

Tanker Shipping Trade Awards 2017

Seatrade Maritime Awards Middle East, Indian Subcontinent Africa 2017

Environmental Leader Top Product of the Year Award 2017

Maritime Innovation Award 2016

The Hutchison Ports Environment Award 2016

Clean Shipping Award 2016

Innovation Technology Award 2015

Technical Innovation Award 2015

Environmental Protection Award (Marine) 2015

Innovative Technology Award (2014)

Stephan Martinussen, Maersk Line’s Head of Global Vessel Performance Centre

Philip Hammond, OffShore Projects Manager at ADEDE Search & Recovery

Mark Morris, Asset Management Director at High Speed Two (HS2) Ltd

Jim Walsh, Advisor & MD at ACT Global Grp

Jesper D. Rasmussen - Maestro Technical Shipmanagement Ltd